Condition Monitoring, Fault Detection and Fault Tolerant Control

Often combining elements of Artificial Intelligence (AI) and Machine Learning (ML), Condition monitoring and fault detection are critical technologies in modern engineering systems. They involve the continuous or periodic assessment of equipment health to detect signs of wear, degradation, or failure before they lead to costly downtime or safety risks.

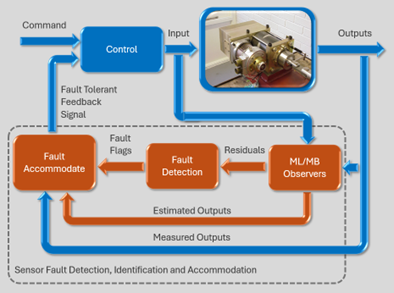

Fault tolerant control/design involves designing systems which continue to operate effectively despite sub-system faults. Often (for safety critical systems) engineers combine the two elements. Designing fault tolerant systems (which degrade gracefully) and leveraging data from sensors, control systems, and machine learning algorithms, to enable predictive maintenance, reduce operational costs, and enhance system reliability.

Condition Monitoring

Monitoring system health to enable predictive maintenance and minimise downtime.

Fault detection and diagnosis

Detecting faults early to improve safety, reliability, and operational continuity.

Fault-tolerant control

Designing resilient systems capable of operating safely under fault conditions.

Applications of Condition Monitoring, Fault Detection and Fault Tolerant Control

Our work integrates machine learning, model-based diagnostics, and AI-driven monitoring systems to improve the reliability and performance of complex engineering systems—particularly in railway, energy, aerospace and other mechatronic applications. Including:

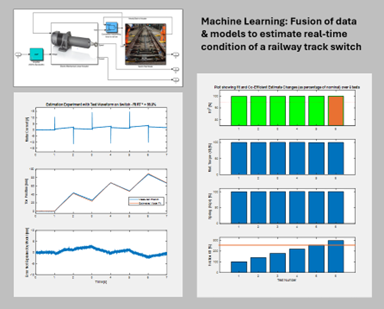

- Condition Monitoring: Developed and deployed model-based and data-driven monitoring systems for railway infrastructure, gasifiers, and industrial actuators. Including model-based and data-driven ML approaches for actuators, wind-turbines, railway track-switches and for adhesion level estimation at the wheel rail interface.

- Fault Detection & Diagnosis (FDD): Applied observer-based and residual-based techniques for early fault identification and re-configuration in a variety of electromechanical and pneumatic actuators, also in track-switches, gas-turbines, flight surfaces, and for cryogenic plant (for fusion).

- AI & Machine Learning is inherent in much of the above, however specific AI methods include integration of FFT-based segmentation, neural networks, and PCA/KPCA methods for acoustic and sensor-based fault detection, and decision making (post fault) to ensure system safety.

- Fault Tolerant Systems: a number of innovations have been developed including fault-tolerant actuators for aircraft engines, railway track switches, and development of novel high-redundancy actuators (inspired by the principles of biomimetics). Sensor and model integration also allows for sensor fault tolerance in a wide range of engineering applications.

Get in Touch with Our Experts

Reach Out to Retech Innovations

We are eager to assist you with your engineering needs. Whether you have a specific project in mind or need guidance on how these technologies can benefit your business, our team is here to help. Contact us today to start a conversation about your requirements.